The robot arm project: light weight, portable and affordable:

Design target: to build a light weight robot arm for remote inspection and automation.

Specifications:

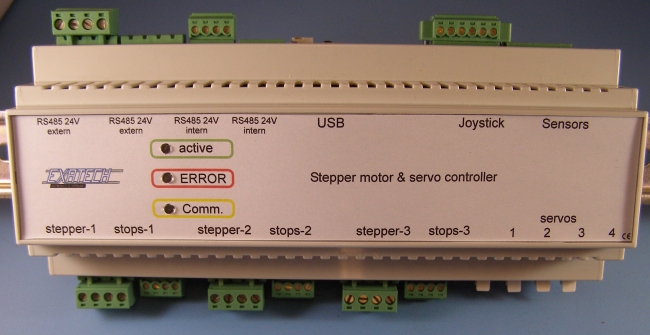

Control unit:

The robot arm is controlled from a (netbook) PC through a USB port. The USB connects to an electronic control unit that was designed

by Exatech bv specifically for the arm. It has outputs for 3 stepper motors and 4 servo motors, has inputs for end-switches, sensors and a

joystick. The control unit can be DIN rail mounted and contains a powerful ARM-7 processor running at 48MHz.

Two RS485 ports are available, supporting Modbus communication over the external port while at the same

time communicating with extension modules such as the DIN rail mounted ConSensus modules

over the internal port.

More information:

The arm has been made by Exatech bv, developers of electronic controllers and embedded software, to demonstrate the feasilibity of a low cost and light weight arm. We welcome any partnership or investor to bring the prototype to production and to develop applications for it. Possible fields of interest: